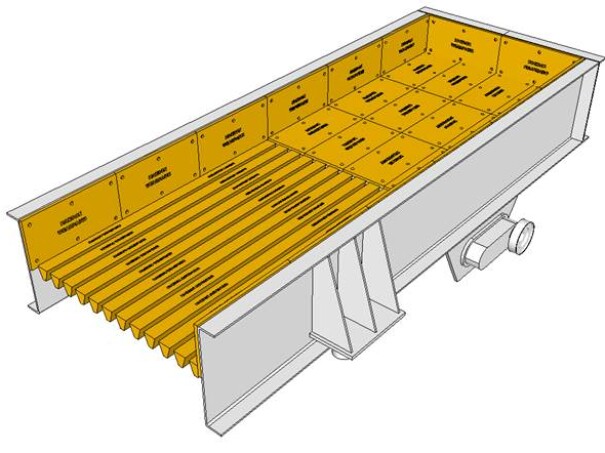

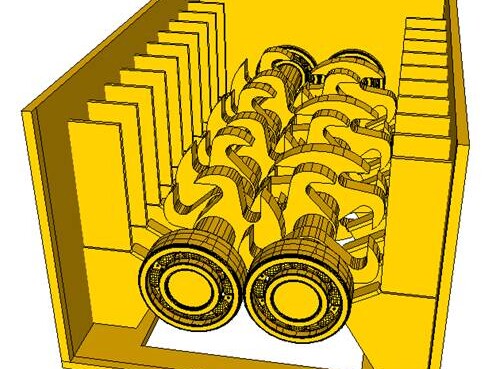

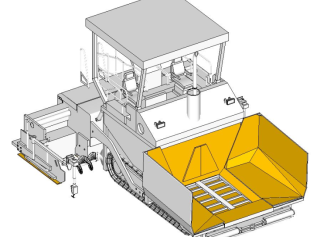

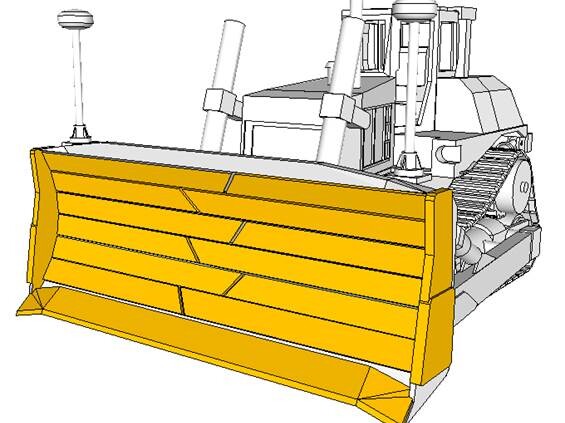

Wearparts in:

Agriculture.

Recycling.

Quarry.

Cement.

Concrete.

Mining.

Construction.

Roadbuilding.

Ready to use

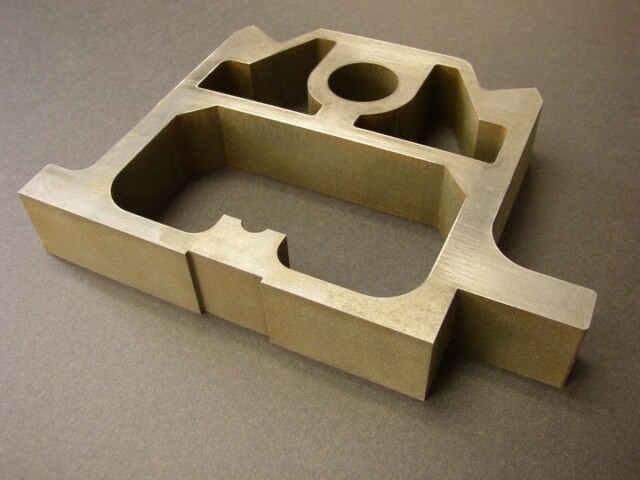

Ready to use Hardox® Wearparts including Drilling & Tapping. From single prototypes to production runs.

AWJ MACHINED

All our Wearparts are machined using OMAX® USA Abrasive Waterjet Machine resulting in ZERO Material Distortion

SSAB Member

We are the official Hardox Wearparts Member & all our products are warranted.

Your uptime is our mission

With India’s Largest & Most Advances Waterjet Job-Shop we can handle single job sizes upto 4000mm x 2000mm x 200mm & 60 HRC with tolerances as low as 50 microns.

Products

WhY hardox?

Hardox® wear plate is the world’s leading abrasion-resistant (AR) steel. Hardox® is hard through and through, from the surface deep down to its core, giving you extended service life and high productivity in the most challenging environments. Available in upto 60HRC.

Why waterjet?

Though conventional cutting methods like laser & plasma are possible on some grades of Hardox it will still change the material properties, microstructure & the edge will be susceptible to micro cracking.This phenomenon is known as HAZ or (HEAT AFFECTED ZONES).

Grades like Hardox 500 & above are always recommended to be processed with AWJ (Abrasive Waterjet) as this process does not leave behind any HAZ. Moreover the edge finish is far far superior when cut with AWJ.

Techaids has India’s Largest & Most advanced waterjet job-shop with 4 OMAX USA machines.

Get in touch.

- D-121-122 Indl. Area Phase VII, Mohali Chandigarh, Punjab

- hardox@techaids.in

- +91 99888 99988

- +91 9216 333 999